Our Ingredients & Process

How We Deliver 46 g Protein per 100 g in an Everyday Staple

Ingredient Composition: Whole Wheat + Wheat Protein Fraction 60%, Soya Fraction 30%, Peanut Fraction 10%

MILLD PROTEIN ATTA IS NOT MADE BY SIMPLY MIXING REGULAR FLOURS.

It is produced using a hybrid protein enrichment and structuring platform that combines advanced dry fractionation, controlled wet protein extraction, and functional protein reconstitution.

This approach allows us to deliver 46 g of protein per 100 g while preserving dough elasticity, handling, and traditional roti taste.

1. Process Overview

Milld’s protein system integrates three scientifically established techniques:

-

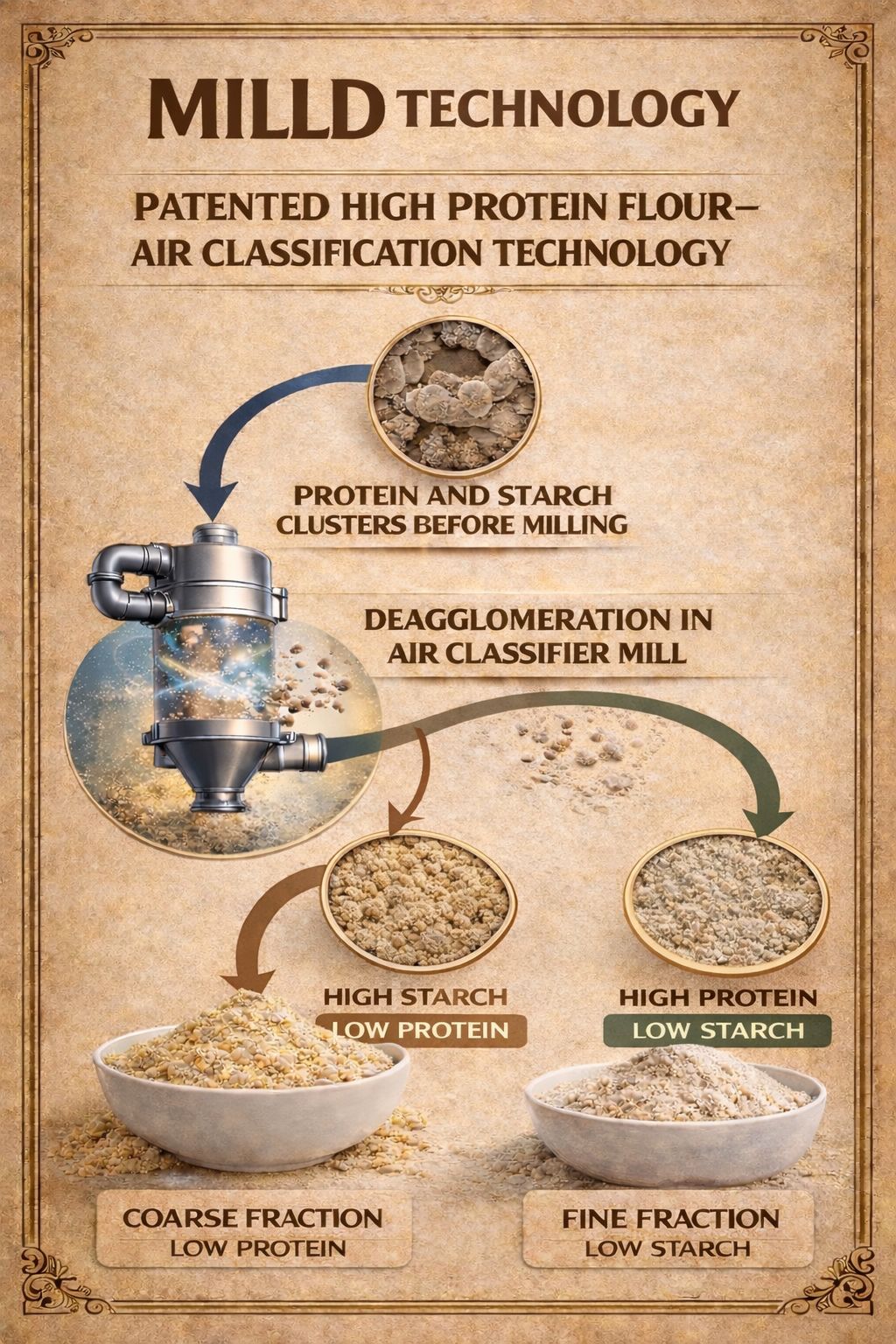

Dry Fractionation / Protein Shifting

(Ultrafine milling + air classification) -

Wet Protein Extraction – pH-Shift “Wave Process”

(Solubilization → separation → isoelectric recovery → re-neutralization) -

Functional Reconstitution

(Protein network formation for dough strength and roti texture)

This controlled combination creates a high-protein, functional composite flour, not a brittle or chalky protein blend.

2. Ingredient 1: Protein-Structured Wheat Fraction (60%)

Purpose:

Transform wheat into a high-protein functional base, rather than conventional atta.

A. Pre-processing & Fractionation

- Wheat is cleaned, tempered, and conditioned to stabilize moisture.

- Milling and controlled separation isolate protein-bearing wheat fractions from starch-heavy streams.

B. “Wave Process” (pH-Shift Protein Structuring)

This is a globally accepted protein science principle adapted for cereal proteins.

- Wheat protein fractions are dispersed in an aqueous phase.

- Alkaline pH adjustment increases protein solubility, releasing proteins from the starch matrix.

- Insoluble starch and fibre are separated through filtration or centrifugation.

- pH is returned toward the isoelectric point, causing proteins to precipitate.

- Proteins are recovered, washed, and dewatered.

- Re-neutralization allows proteins to reorganize into a functional elastic network.

- Low-temperature drying preserves functionality.

Result:

A protein-enriched wheat fraction with significantly higher protein than normal wheat flour, while retaining dough elasticity and kneading stability.

3. Ingredient 2: Soy Protein Fraction (30%)

Purpose:

Deliver clean, high-quality plant protein with reduced fat and controlled flavour.

A. Stabilisation

- Soybeans are cleaned, dehulled, and mechanically processed.

- Oil removal increases protein concentration and shelf stability.

- Controlled heat or enzyme treatment reduces undesirable compounds.

B. Protein Enrichment

Two enrichment pathways may be used depending on purity targets:

Dry Protein Shifting

- Ultrafine grinding creates a particle size distribution.

- Air classification separates:

- Fine, protein-rich particles (<20 µm)

- Coarser carbohydrate-rich fractions

Optional pH-Shift Extraction

- Protein solubilization at controlled pH

- Separation of insolubles

- Isoelectric precipitation and recovery

Result:

A defatted, high-protein soy fraction suitable for daily staple consumption.

4. Ingredient 3: Peanut Protein Fraction (10%)

Purpose:

Enhance protein density, amino acid diversity, and taste—while controlling fat.

Protein Enrichment

- Ultrafine milling and air classification separate protein-rich fines.

- Optional pH-shift is used when higher purity is required.

Result:

A protein-enriched peanut fraction with stable performance in composite flour systems.

5. Why This Technology Works

-

Dry fractionation uses particle physics:

- Starch remains coarser

- Proteins concentrate in fine particles (<20 µm)

- No water or chemicals required

-

Wave Process (pH-shift) enables:

- Higher protein purity

- Controlled functional behavior

- Stronger protein networks

-

Composite protein design (wheat + soy + peanut) delivers:

- Complete amino acid profile

- Stable dough handling

- Familiar roti taste and texture

6. Compliance & Transparency Statement

Recommended Website Line:

“Protein values are calculated based on ingredient specifications and validated through batch-wise NABL-accredited laboratory testing. Natural agricultural variability may cause minor deviations.”

Ingredient Declaration

Whole Wheat & Wheat Protein Fraction (60%), Defatted Soy Fraction (30%), Defatted Peanut Fraction (10%)

Allergen Declaration

Contains:

- Wheat (Gluten)

- Soy

- Peanuts

This product is manufactured using wheat protein fractions, defatted soy fractions, and defatted peanut fractions.

Important Information for Consumers

- Not suitable for individuals with wheat/gluten allergy, soy allergy, or peanut allergy.

- Contains naturally occurring gluten from wheat.

- Manufactured in a facility that handles cereals containing gluten, soy, peanuts, and other nuts.

Advisory Statement

People with food allergies should read ingredient information carefully and consult a healthcare professional before consumption.

Transparency Promise

Milld believes in full transparency.

👉 Visit: www.MillD.com